flux cored mig welding sheet metal I tried to find the easiest way to weld thin sheet metal with flux core. Flux core is usually used for heavier metals and is not . Shop for Recessed Electrical Boxes in Electrical Boxes. Buy products such as Arlington DVFR1W-1 Recessed Electrical/Outlet Mounting Box, Single Gang at Walmart and save.

0 · what is flux mig welding

1 · mig flux core welding basics

2 · is flux core welding strong

3 · flux welding for beginners

4 · flux cored welding techniques

5 · flux core welding videos

6 · flux core welding for dummies

7 · flux core mig welding techniques

$7.24

what is flux mig welding

In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of . I tried to find the easiest way to weld thin sheet metal with flux core. Flux core is usually used for heavier metals and is not .

mig flux core welding basics

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .

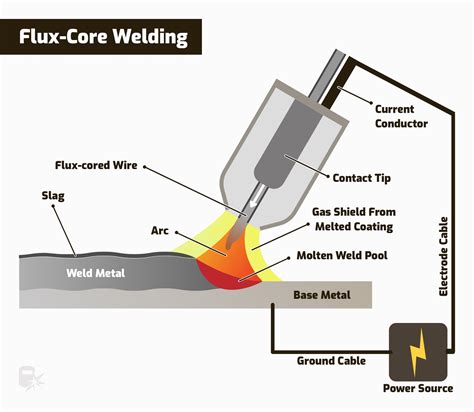

Flux core welding is an advanced welding technique that uses a special shielding gas to join metallic materials. Unlike gas metal arc welding (GMAW), flux core requires a shielding gas and the ability to arc weld without .

Eastwood Co makes a great low cost Flux Core welder that can MIG weld with a future purchase of a gas regulator, hose, appropriate MIG wire, and gas tank. . Once you settle on your welder, flux core welding thin sheet .

Metal preparation for flux-cored welding. As mentioned earlier, flux-cored welding is more tolerant of surface contamination than MIG welding. However, you should always clean the surface of the base metals as . #welddotcomLets weld some thin material with flux core!Join Weld.com today, get member’s perks and support the community! https://www.youtube.com/channel/UCM.

Today we are going through some more gasless welding tips and tricks using flux core wire and looking at 4 ways you can spot weld thin sheet metal. Each one .

is flux core welding strong

Wondering if it's possible to butt weld automotive sheet metal with a flux core welder? This video can help answer that question by using a Harbor Freig. For panel rust in a jap car with thin sheet metal, is flux core going to work? If so, what type should I use? Are there any places I can go to watch/read automotive specific mig flux welding? Any sort of advice or information would be great! Cheers, Luca . Shoggi Member. Messages 238 Location Bradford west yorkshire. In this comprehensive guide, we'll delve into the intricacies of MIG welding sheet metal and explore the ideal settings for different metal thicknesses. From. . Welding Thin Sheet Metal With Flux Core: Expert Tips & Tricks; How To Braze Copper Water Pipe: Expert Tips for Beginners; Types Of Welding Positions: Master the Basics and Beyond . Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. . Avoid flux-cored wires because they input far more heat into the metal. The flux-cored wires are hollow. The cross-sectional area of the steel wire is small, which increases the current (heat) concentration flow into the welding .

MIG Welding Wires. In Gas Metal Arc Welding (GMAW), you won’t be using a stick electrode or a filler rod. . The most common sizes for welding on sheet metal are 0.35 and 0.45. MIG Wire selection chart – See full-size version here Wire Quantity. . the welding process is known as either Gas-Shielded or Dual-Shielded Flux-Cored Welding, . Choosing between Flux core and MIG welding can be tough, especially if you don’t know much about welding. . The amount on slag and spatter produced when welding metal with either Flux core or MIG. Flux core has flux at the center of its welding wire that produces slag when welding. . 5 Best Welders for Sheet Metal – for Your DIY Work . Flux core welding (FCAW) is much easier to learn and master than stick (SMAW) or TIG welding (GTAW), but it can present many challenges for beginner welders. . 0.030” wire will weld 20 gauge to 14 gauge sheet metal, and 0.035” wire will weld 18 gauge to 3/16” thick steel. . You can’t use the same rollers for MIG that you would with .

If you're wondering if you can use a flux core, gasless MIG welder for auto body work, this video will answer that question so that you can make an informed .

MIG Yes. MIG welding stands for "Metal- Inert Gas." By definition MIG requires a bottle of inert shielding gas, often 25% CO2 and 75% Argon. . That doesn't magically make it a good choice for things like sheet metal, though. Flux core is a high heat, high current process. The flux makes the arc hotter, denser, and more conductive leading to .

Lincoln Electric ED030584 is an excellent flux-cored welding wire that is strong, mild steel and has excellent welding properties. And this is one of the best flux core wire for sheet metal, sheet metal heat and for general weld applications. 2. YESWELDER E71T-GS Flux Core Gasless Mig Wire The higher your heat input, the greater your weld crater issues, get into the habit of filling the weld crater, by either welding back and forth over the weld pool, (pipe welders on the root), stopping and allowing the extra weld . Can the Titanium Easy-Flux 125 Flux Core Welder be used for Auto Body Repair? Lap, butt and plug welds are demonstrated on 22 gauge (.030") auto body sheet .Generally, mild steel is used as the base material when flux welding sheet metal, and the welding rod should be made of the same material. . No, flux core welding is not the same as MIG welding. Flux core welding is a type of welding process that uses a continuously fed tubular electrode containing a flux compound along with a gas-shielded wire.

Select the department you want to search in . Techniques for Welding Thin Sheet Metal with Flux Core. When welding thin sheet metal with flux core, using the right techniques is crucial for achieving clean and strong welds. Here are some techniques to consider: Controlled heat input. Thin sheet metal is sensitive to excessive heat, which can cause distortion and warping.

Transform thin metals into sturdy constructions with sheet metal welding. Get expert tips on MIG and TIG techniques – start perfecting your skill now! . Can you weld sheet metal with flux core? While flux-core welding sheet metal is feasible, it requires careful heat management to avoid warping or burn-through due to its higher heat input . Which welding method is better for a beginner: flux core or MIG welding? Both flux core and MIG welding can be suitable for beginners. Flux core welding is often forgiving and better for outdoor conditions, making it an excellent starting point. MIG welding, while versatile, may have a steeper learning curve but offers precise control and clean . To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. Now you can go to power block tv and look at welding body panels. Which is the stitch or tack method. . But where it when wrong is you can weld flux core on a mig welder. So its miss used as to what one is really doing. Should not the . The best welders for sheet metal is a MIG or TIG welder due to their precision and control. Key specifications include a wide amperage range for better . Welding Processes: MIG/Flux-Cored ; Duty Cycle: 10% @ 105A ; Amperage Range: 50 – 120A ; Input Voltage: 110V ; Accessories: MIG Torch, Ground Clamp, Flux-Cored Wire ; Weight: 35 lbs; Pros.

fabrication with metal mesh

I am trying to mig weld some 1.1mm (about 19 gauge) steel. I have an sip hg2300mp mig/tig/arc combo machine. Wire feed 1-10, voltage 13-23v. I have been trying to weld with 0.8mm flux core wire (to save money on gas) wire speed range 1-3 voltage range 13 - 16v. Attempting to run eeee's puts.

I've made videos in the past about welding 22 or 24 gauge steel with gas-less flux core wire, I thought I'd give it one more shot here after being a little m. Today we're flux core welding sheet metal. Last time we did a thin gauge flux core welding video we used 1/8" and got completely hammered for it not being th.

It can only handle MIG and flux-cored welding, which doesn’t give you too many options. But for welding sheet metal, this welder works perfectly fine. . For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you the most control and versatility. The Reboot MIG welder supports both flux-cored .

flux welding for beginners

flux cored welding techniques

flux core welding videos

$21.95

flux cored mig welding sheet metal|mig flux core welding basics